Birdair to Brighten Up George Bush Intercontinental Airport with ETFE Canopies

TensoSky® ETFE canopies to provide practical and aesthetic appeal to IAH Airport Terminal B

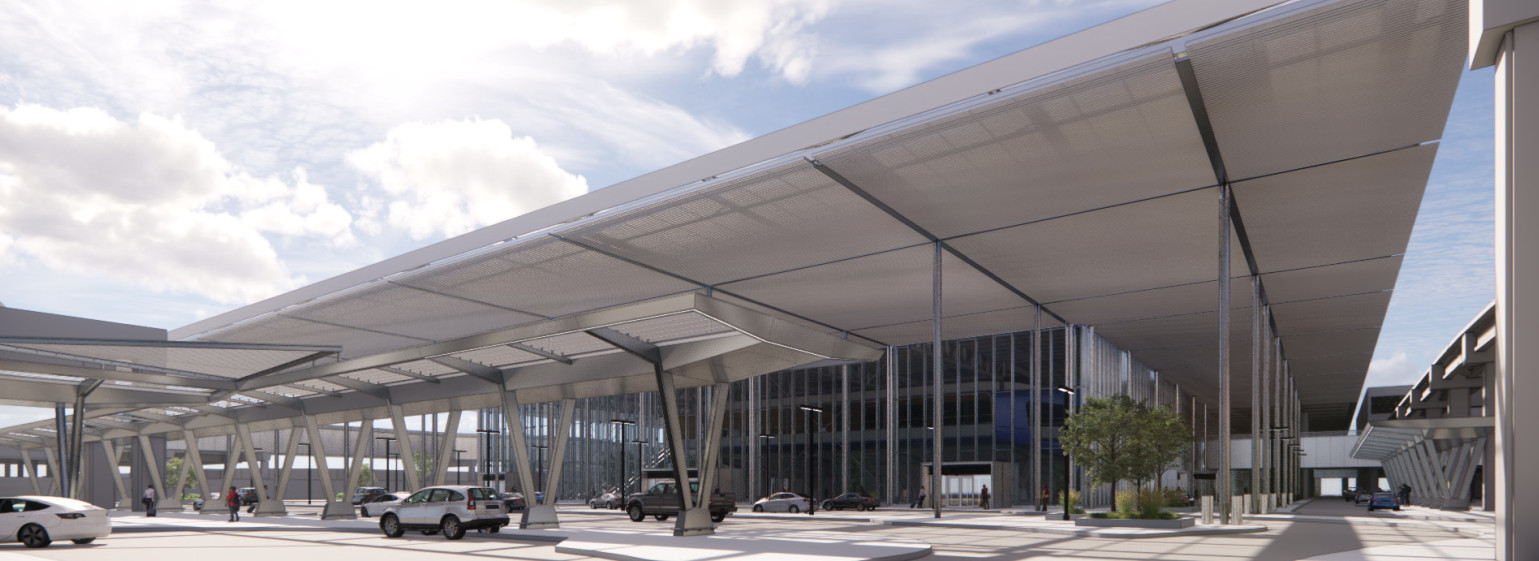

Birdair, Inc., the world’s leading specialty contractor for custom tensile membrane structures for over 68 years, is elevating the functionality and aesthetic appeal at George Bush Intercontinental Airport (IAH) in Houston with a series of ETFE canopies and walkway canopies. The Terminal B renovation project, part of the $2.6 billion overall renovation at IAH, will include approximately 80,000 sq. ft. of covered area provided by Birdair’s TensoSky® ETFE canopies.

The transparent, single-skin ETFE canopies featuring a standard frit pattern to help with solar heat gain, supported by stainless-steel cables, will provide weather protection for arrivals and departures at the new United Airlines terminal, as well as walkways leading to parking garages. The canopies are designed with a fritted pattern to manage light and temperature while optimizing energy efficiency.

“Birdair is excited that our TensoSky® ETFE canopies will be showcased as part of the beautiful new Terminal B at IAH Airport,” said Dave Capezzuto, Senior Vice President of Operations & Pre-Construction, Birdair. “The canopies will not only provide a stunning visual effect but will result in a brighter, more open environment for the thousands of travelers who pass through IAH every day.”

Birdair’s scope of work includes providing its TensoSky® ETFE film, cables and attachment hardware. Additional members of the project team include Clark Construction, a leading provider of general contracting, design-build, construction management and specialty contracting services; Page, a multidisciplinary design, architecture and engineering firm; and Walter P. Moore, a global, integrated team of expert creatives.

Birdair’s construction team will consist of 15-20 workers using primarily man lifts and scissor lifts. Construction is set to begin this summer and take approximately five months.

TensoSky® ETFE is a new-generation material that goes beyond glass. Durable, highly transparent and very lightweight in comparison to glass structures, ETFE film is considered the material of choice for everything from traditional skylight applications to long span structures and building facades. Few building materials can match TensoSky® ETFE for its impact or presence when designing a structure that stands out from the crowd.

Due to low coefficient of friction of its surface, dust or dirt will not stick to TensoSky® ETFE film. It is also highly transparent (from 90 to 95%) and allows for the passing of UVs, which are responsible for the promotion of photosynthesis thus facilitating plant growth. While ETFE films are very elastic (up to 600% at breaking point), they are still structurally resistant and do not degrade under exposure to environmental pollution, UV light, harsh chemicals or extreme temperature variations.

TensoSky® ETFE film has approximately 70% acoustic transmission. Little energy is consumed from extrusion of the film to transportation to site compared to other similar cladding material, resulting in a reduction of the overall carbon footprint. In addition, ETFE systems provide ample natural daylighting, minimizing energy costs by lowering the demand for indoor lighting. Waste from the manufacturing process or even old ETFE elements can be remolded into new ETFE products such as tubing components, wires or castings.

Located 23 miles north of downtown Houston, IAH served over 48.4 million passengers in 2024. With 25 passenger airlines offering nonstop service to over 180 destinations, it is a primary hub for international travel.

A full-service design-build specialty contractor for tensile architecture, Birdair offers a comprehensive range of pre-construction services including design assistance, budgeting, construction methodologies and project schedule development. Birdair’s in-house capabilities include design development, engineering, fabrication, construction (installation) and service and warranty services.

For more information on Birdair’s innovative roofing systems, canopies and skylights, visit Birdair.com and follow Birdair on Facebook and LinkedIn.

###

About Birdair

Birdair, Inc., is the leading specialty design build contractor of custom tensile structures around the world. In addition to pre-construction services such as design assistance, budgeting, construction methodologies and project scheduling, Birdair provides design-build solutions in all aspects of project design, fabrication, installation and maintenance. The company offers a selection of architectural fabric membranes, including PTFE fiberglass, TensoSky® ETFE film, PVC and Tensotherm™, an insulated tensioned membrane system. Birdair, based in Buffalo, NY, is a member of the Taiyo Kogyo Group, with operations serving North and South America and other international locations. For more information about Birdair, call 1-800-622-2246 or visit Birdair.com.

Contacts:

Pipitone

Chris Hayes

Content Strategist

chayes@pipitone.com | 412.321.0879

Birdair

Michele Roth

Director of Marketing

mroth@birdair.com | 716.633.9500